Coal Dust Explosion and Prevention

In previous post we have discussed about Fire damp Explosion. Now in this post we will discuss a detail about

The sharp coal cutter and good explosive is selected, this will reduce the formation of coal dust.

1. Coal Dust Explosion.

&

2. How to prevent it?

You May also like To Read These....

Let's Begin....

Coal Dust Explosion

To explode the coal dust, it has to be suspended in air as a cloud, which is capable to burst and propagate through out the mines. This propagation is due to the presence of coal dust through out the mines. As only 1g/c.c is required for propagation and it is known that no part of mines is free from that.

Before explosion the coal dust should be in the form of cloud in air and the density (30 to 40g/cubic meter) of this so much that no can see through it. To explode coal dust only sufficient density and ignition source is required.

As we have discussed in previous post that the Fire Damp Explosion is followed by this explosion. This is because after Fire Damp Explosion provides a suitable condition for the explosion of Coal Dust. This means not that this explosion is always followed by Fire Damp Explosion.

* Ignition temperature of dust-air mixture is 700 to 800℃.

Inflammability

The inflammability of coal dust is defined as the spread of flame from the source of ignition.

So that the inflammability is depends on different factors.....

1. Presence of volatile matter

2. Finesses of particle

3. Percentage of combustible material

4. Moisture

5. Fire Damp

6. Intensity of ignition source

&

7. Dust Distribution

8. Age of coal Dust

Prevention of Coal Dust Explosion

The Explosion can be prevented By...

1. Reducing the formation of coal dust

2. Prevent to spread

Now we will know one by one....

1. Reduce Formation of Dust

At working face

To reduce the formation of dust we have to use "water infusion method".

In this method holes are drilled at face at 45° and water is injected under high pressure till it will visible at the coal face.

At coal cutting picks water sprayer is installed which helps to suppress the coal dust.

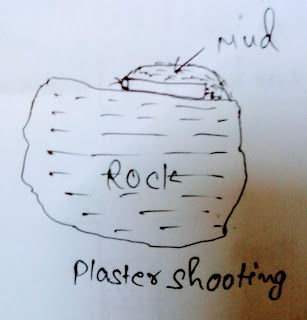

The sharp coal cutter and good explosive is selected, this will reduce the formation of coal dust.

During Transportation

The coal is transported from mines by different mean of transportation system.

If coal is transported by tubs, it should be sprinkle proof and haulage track are so that there will no derailment.

In case of "conveyor belt", it is properly aliened and installed that spillage is avoidable.

The air current of the convey roadway should be minimum.

Water is spraying at the loading point and the dust to extractor is used to extract from belt conveyor.

Some steps are taken to render the Coal Dust to be harmless..

1. Wetting the Dust by Water

Spraying of water on sides, roof, floor are used but it will increase the humidity inside the mines. So, it is used for local purpose as for transfer point and loading point.

The chemical mixture of like calsolene oil is used to wet the dust and this will effect for longer time.

2. Spraying or sprinkling of Stone dust

Stone dusting is a process by which concentration of coal dust is reduces and helps to render the coal dust.

3. Making of stone dust or water barrier

These two has it's own importance because it plays an important role during explosion. This technique reduces the formation of cloud.

* In the next post we will discuss in detail about the making of stone dust barrier...

Still you have any questions from above explained, please comment me below...

And if you need a respiratory protection against dust and smoke, you may want to pick an excellent face masks from Drager to do that job. Number One Drager Distributor in the Philippines.

ReplyDelete