Secondary Blasting Technique

In this post we will deal about the Definition of Secondary Blasting and types of Secondary Blasting. Some other Blasting are also available you can read about that. So let's start...

Definition of Secondary Blasting

The technique used to blast the boulders to achieve the fragmentation is called secondary blasting. This blasting is done to get the rocks which can be easily handled.

Why and how to do secondary blasting?

Why secondary blasting?

We does secondary, in case when the primary blasting don't give fragmentation of rock which can be easily handled.

The secondary blasting is followed after the primary blasting.

How to do secondary blasting?

To do secondary blasting we have to follow some methods which will give us batter resultant. These are here

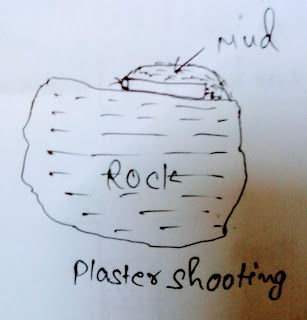

1. Plaster shooting or Mud Capping..

As name indicates mud capping, the primer cartridge is place at top of Boulder and covered with mud. The blasting is done from the safe place by electric detonator.

The explosive and detonators are plaster gelatin and ordinary electric detonator respectively.

2. Pop shooting...

In pop shooting a hole of 30mm dia. is drilled of the length of 30cm to 50cm in the Boulder.

The special gelatin is used as the explosive and the detonator will be ordinary or delay.

3. Snake Blasting..

A hole is drilled below the Boulder. Explosive is charged in the hole and stemmed sand. The blasting is done by electrically from the safe place.

P1 or special gelatin is used as explosive.

4. Deck Blasting...

In this method of secondary blasting, charging of explosive and stemming of hole is done alternatively to the whole length of hole. This is adopted due to the bench of open cast mining is consist of alternative layer of hard and soft rock.

In this method the two third of explosive is charge at the bottom of hole which is primed. After this a layer of stemming is done to length of soft rock. The remaining one third of explosive is charged, after this a layer of stemming is done. This give us a good fragmentation from bottom to top.

5. Chamber Blasting..

The chamber blasting is performed in opencast mining because in higher benches the large area get charged with explosive and a small area is stemmed which results the blow out of hole. To avoid this the chamber blasting is adopted.

6. Muffled Blasting...

The muffled blasting is performed by covering by the surface to avoid accident of flying rocks.

This covering is done because blasting is heavy and the mines is near to population area.

The cover is made up of grid of steel. The rod is of 2.5cm dia. and distance between the rods in grid of 15cm to 25cm. The sand bag is placed on the steel grid.

7. Cushion Blasting...

When it is desirable to get the lumpy coal to reduce the dust, then cushion blasting is done.

In this blasting high explosive with low density is used.

The charging of holes with explosive followed by air bags which works as cushion. The remaining hole is stemmed by stemming material.

8. Simultaneous Blasting...

In this blasting number of holes are blasted at a time, such blasting is called simultaneous blasting. The holes are charged with explosive and the detonators are of low tension. The series connection is generally preferred.

Definition of Secondary Blasting

The technique used to blast the boulders to achieve the fragmentation is called secondary blasting. This blasting is done to get the rocks which can be easily handled.

Why and how to do secondary blasting?

Why secondary blasting?

We does secondary, in case when the primary blasting don't give fragmentation of rock which can be easily handled.

The secondary blasting is followed after the primary blasting.

How to do secondary blasting?

To do secondary blasting we have to follow some methods which will give us batter resultant. These are here

1. Plaster shooting or Mud Capping..

As name indicates mud capping, the primer cartridge is place at top of Boulder and covered with mud. The blasting is done from the safe place by electric detonator.

The explosive and detonators are plaster gelatin and ordinary electric detonator respectively.

2. Pop shooting...

In pop shooting a hole of 30mm dia. is drilled of the length of 30cm to 50cm in the Boulder.

The special gelatin is used as the explosive and the detonator will be ordinary or delay.

3. Snake Blasting..

A hole is drilled below the Boulder. Explosive is charged in the hole and stemmed sand. The blasting is done by electrically from the safe place.

P1 or special gelatin is used as explosive.

4. Deck Blasting...

In this method of secondary blasting, charging of explosive and stemming of hole is done alternatively to the whole length of hole. This is adopted due to the bench of open cast mining is consist of alternative layer of hard and soft rock.

In this method the two third of explosive is charge at the bottom of hole which is primed. After this a layer of stemming is done to length of soft rock. The remaining one third of explosive is charged, after this a layer of stemming is done. This give us a good fragmentation from bottom to top.

5. Chamber Blasting..

The chamber blasting is performed in opencast mining because in higher benches the large area get charged with explosive and a small area is stemmed which results the blow out of hole. To avoid this the chamber blasting is adopted.

6. Muffled Blasting...

The muffled blasting is performed by covering by the surface to avoid accident of flying rocks.

This covering is done because blasting is heavy and the mines is near to population area.

The cover is made up of grid of steel. The rod is of 2.5cm dia. and distance between the rods in grid of 15cm to 25cm. The sand bag is placed on the steel grid.

7. Cushion Blasting...

When it is desirable to get the lumpy coal to reduce the dust, then cushion blasting is done.

In this blasting high explosive with low density is used.

The charging of holes with explosive followed by air bags which works as cushion. The remaining hole is stemmed by stemming material.

8. Simultaneous Blasting...

In this blasting number of holes are blasted at a time, such blasting is called simultaneous blasting. The holes are charged with explosive and the detonators are of low tension. The series connection is generally preferred.

I was searching for article...

ReplyDelete