Secondary Blasting Technique

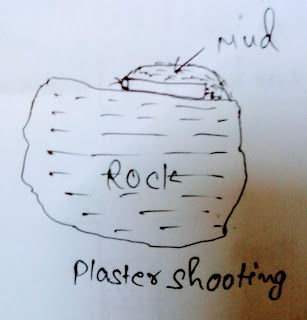

In this post we will deal about the Definition of Secondary Blasting and types of Secondary Blasting . Some other Blasting are also available you can read about that. So let's start... Definition of Secondary Blasting The technique used to blast the boulders to achieve the fragmentation is called secondary blasting. This blasting is done to get the rocks which can be easily handled. Why and how to do secondary blasting? Why secondary blasting? We does secondary, in case when the primary blasting don't give fragmentation of rock which can be easily handled. The secondary blasting is followed after the primary blasting. How to do secondary blasting? To do secondary blasting we have to follow some methods which will give us batter resultant. These are here 1. Plaster shooting or Mud Capping.. As name indicates mud capping, the primer cartridge is place at top of Boulder and covered with mud. The blasting is done from the safe place by electric detonator...